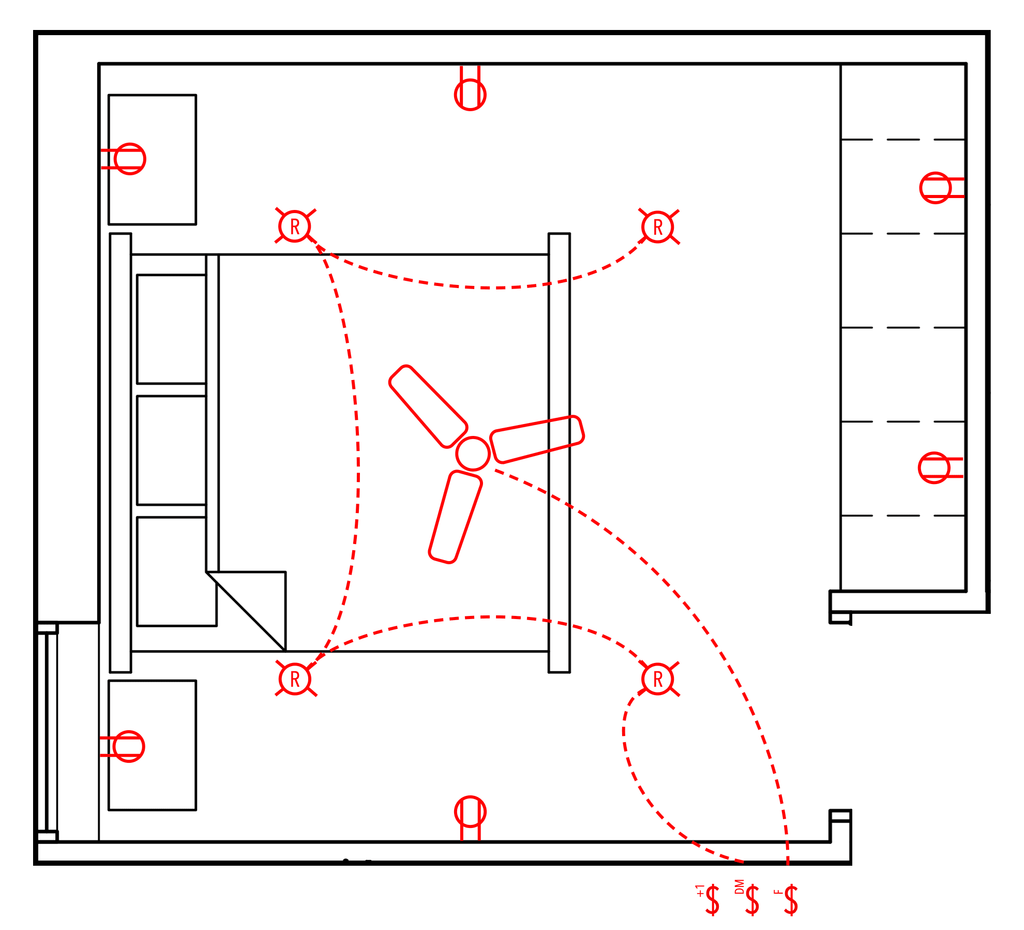

We’re on to the floor now that we’ve done a first pass on the roof. We have to figure out how the first floor walls will transition to the rim joist and basement walls. Mainly, we have to prevent thermal bridging, maintain the necessary R values in the floor, and continue the air barrier. It will also be worth considering floor trusses vs joists, and how to arrange the floor for soundproofing. The spacing of the supports and the type of insulation can affect the latter. As with the first floor ceiling, some sort of service cavity (probably of the cheaper, generic drop ceiling variety) is likely to be used.

NoteThis post is still a work in progress. We’ll be meeting with the architects soon to clarify a few details.

Continuous Insulation

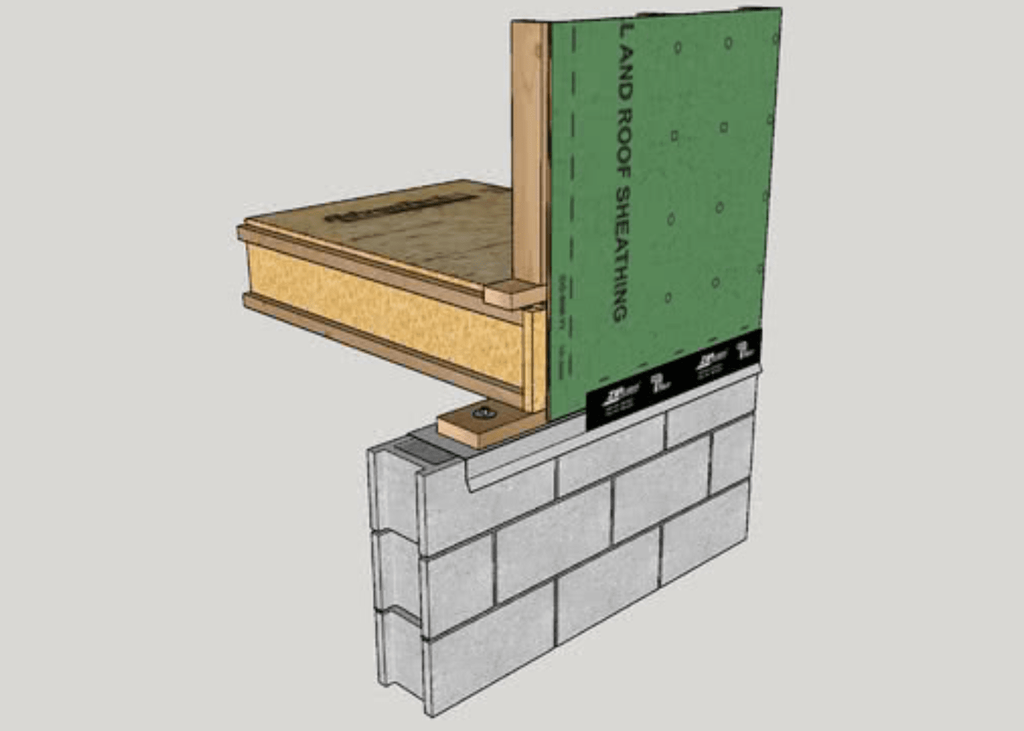

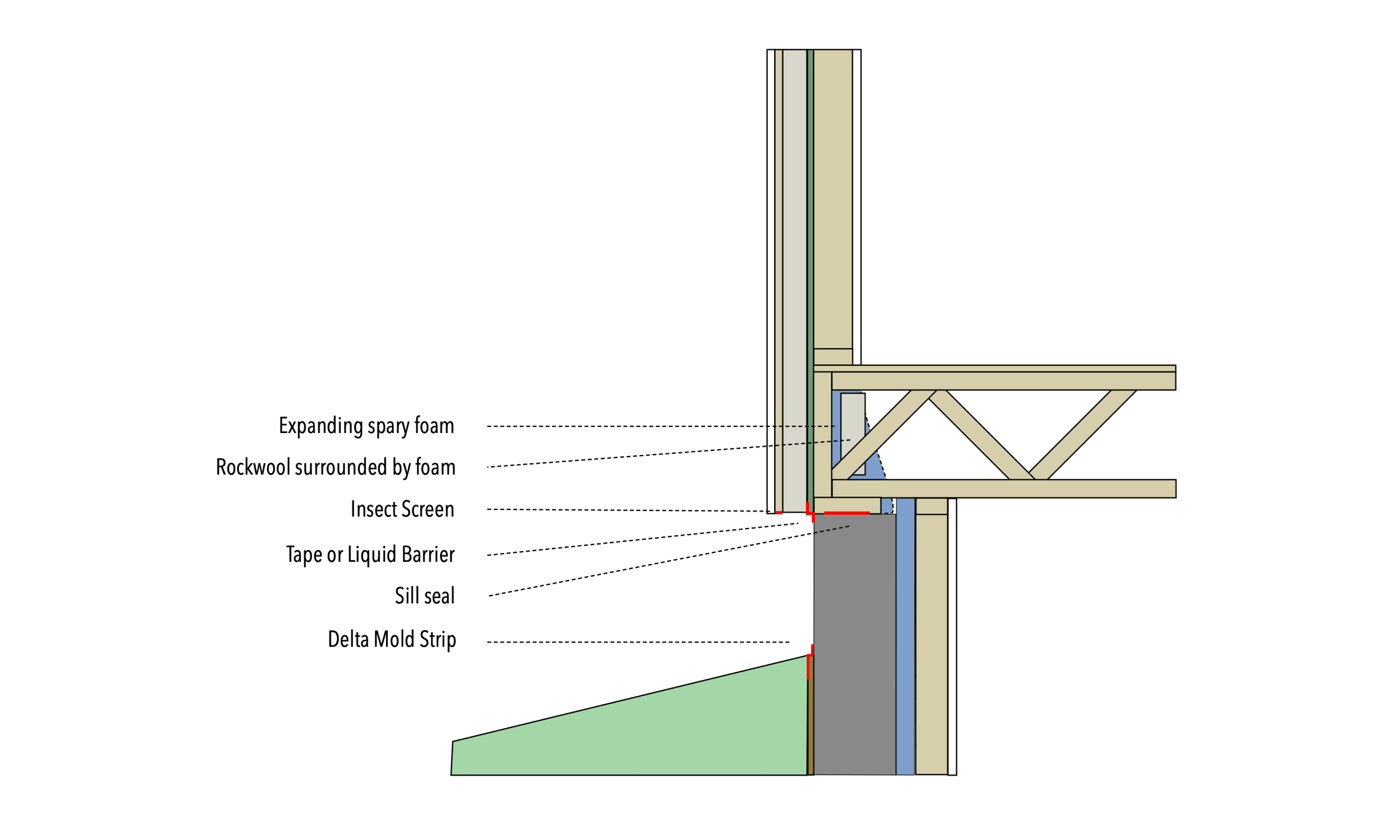

The main point of interest with insulation at the wall to floor transition is that we’ll be moving from exterior continuous insulation to interior. This will all occur at the rim joist. As always, Green Build Advisor has initial templates to provide an overview. With that in mind, we just need to decide how to insulate the rim joist. For starters, spray foam will ensure coverage in an area with so many transitions. It will expand and reduce condensation. After that, we can up to the R value similar to the walls above by placing loosely fitting mineral wool in the cavities.

This video is a good overview of the idea – just imagine he sprayed closed cell foam in there before placing the mineral wool.

Insulating the rim joist.

Another interesting point – it is not too efficient to insulate the basement ceiling. It appears that if you provide continuous insulation down the basement walls and under the slab, it is not necessary to insulate the ceiling.

Air Barrier

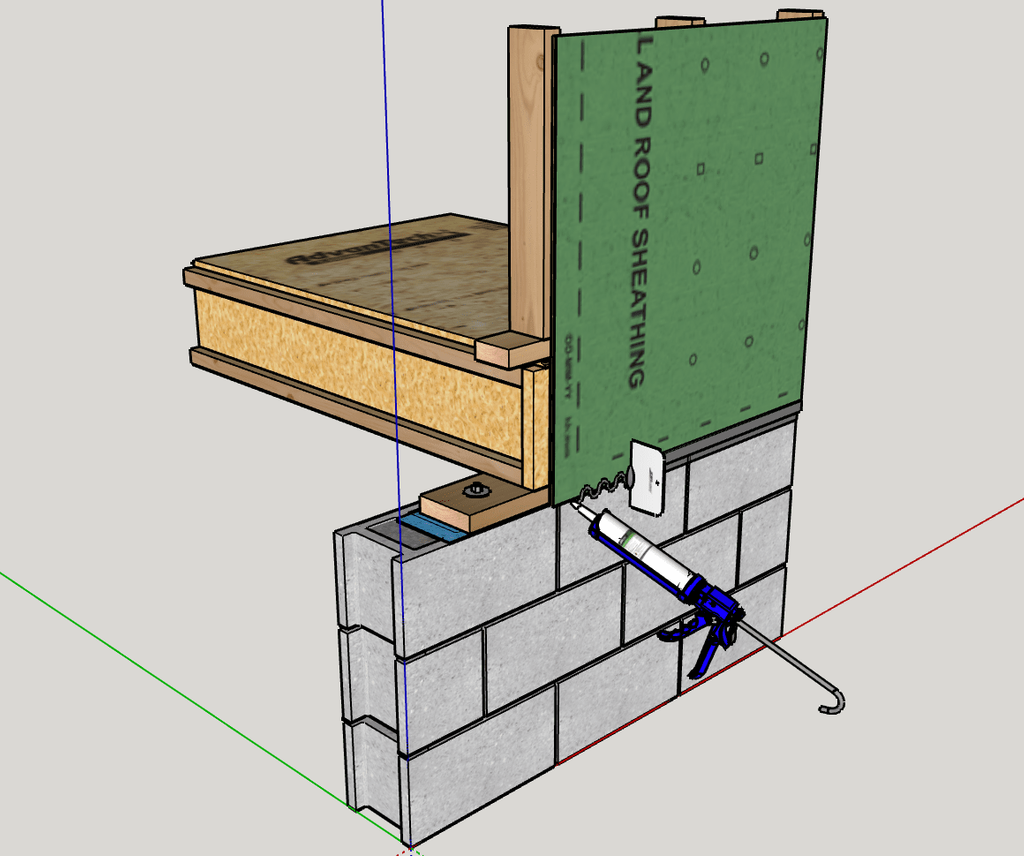

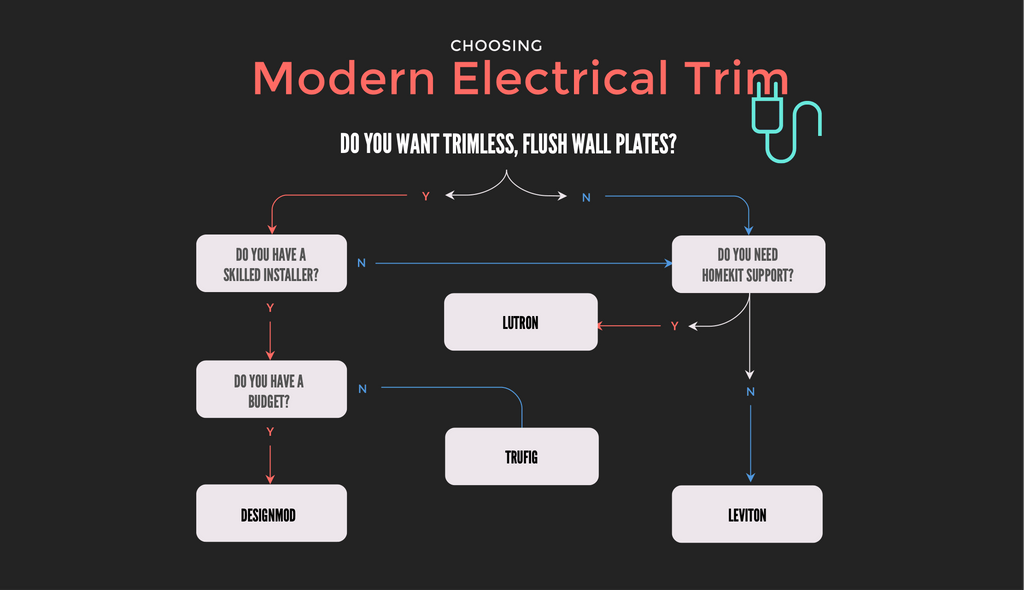

The air barrier is fairly easy to continue down to the foundation wall. Matt Risinger has the best overview covering all of our options. His preferred recommendation of a fluid applied exterior sealant match up with one of Huber’s official recommendations with the Zip system.

If you view Huber’s 3D object, you can change scenes. On scene 3, you’ll see the second image, which seals the Zip sheathing to the concrete wall with something like Prosoco Joint & Seam Filler. Matt also has the two videos below which cover both tape (i.e.: Siga Fentrim or Delta Multi-band) and fluid applied.

Air Sealing The Joint Between Framing & Concrete

Sealing Framing to Foundation

Transition to Ground

We’ll have a Delta dimple screen on the outside of the basement wall. Once we hit ground level, that will have to be sealed off with a Delta mold strip. Have a look:

Installation and Best Practices for DELTA-MS Dimpled Membrane

That’s a pretty straightforward solution. What’s less clear is how we’ll finish off the 6"-8" of foundation wall that show before we reach the siding. To give you an idea of the problem, have a look over these solutions ranging from stucco, brick, fill in and paint. Fill in and plants are preferable, but we still have a problem where the ground slopes down to the exposed basement. For that reason, we may have to pick a siding for the bottom floor that works on concrete, and can transition to the siding of the ground floor.

Floor Design

How should the supporting floor should be designed? We’re leaning towards trusses just because of their open nature, which makes it easier for the other trades. If we go that route, two questions come to mind:

- Should the trusses be 24" OC?

- How deep should the trusses be?

The answer is nicely summed up in this forum post:

Maybe it would help to try an example. Let’s say a guy comes in and wants a 28′ clear span floor. He wants to keep the height down, though, and wants floor trusses as shallow as possible. We start out with a 18″ deep floor truss 19.2″ O.C., which works according to the span charts. I check it with the vibration formula and it comes up at 11.3 Hz – in the marginal range. The customer then asks how about 16″ O.C.? This only increases the Hz to 11.8. What about 12″ O.C.? That changes it to 12.4 Hz. I suggest increasing the depth to 22″ deep This will change the floor to 14.1Hz – A dramatic increase, and pretty close to acceptable.

Basically, deeper trusses have a more significant impact on sturdiness than trusses that are closer together. Here is further discussion to drive the point home. So, we’ll probably go with 24" deep trusses spaced 24" OC.

A final consideration – should we use trimmable trusses like Trim Joist to give us play with the measurements? These trusses allow for a few inches to be cut off on site, instead of having to order a new truss in the event of a bad fit. We don’t have the cost difference at the moment, but that seems to be the only thing that could get in the way.